Starting out - give major points

- Dallas Makerspace, one of the largest volunteer-only run makerspace in the country. Nobody gets paid to be here - we all volunteer to make it what it is

- 36,600 square feet facility - is 24/7, with access controlled by RFID keys

- Give how long you’ve been a member, perhaps what you like to do

- As you walk towards 3D fab, explain that we are organized by committee, which are just collections of members that do certain things - those committees are granted space and funding, and meet monthly

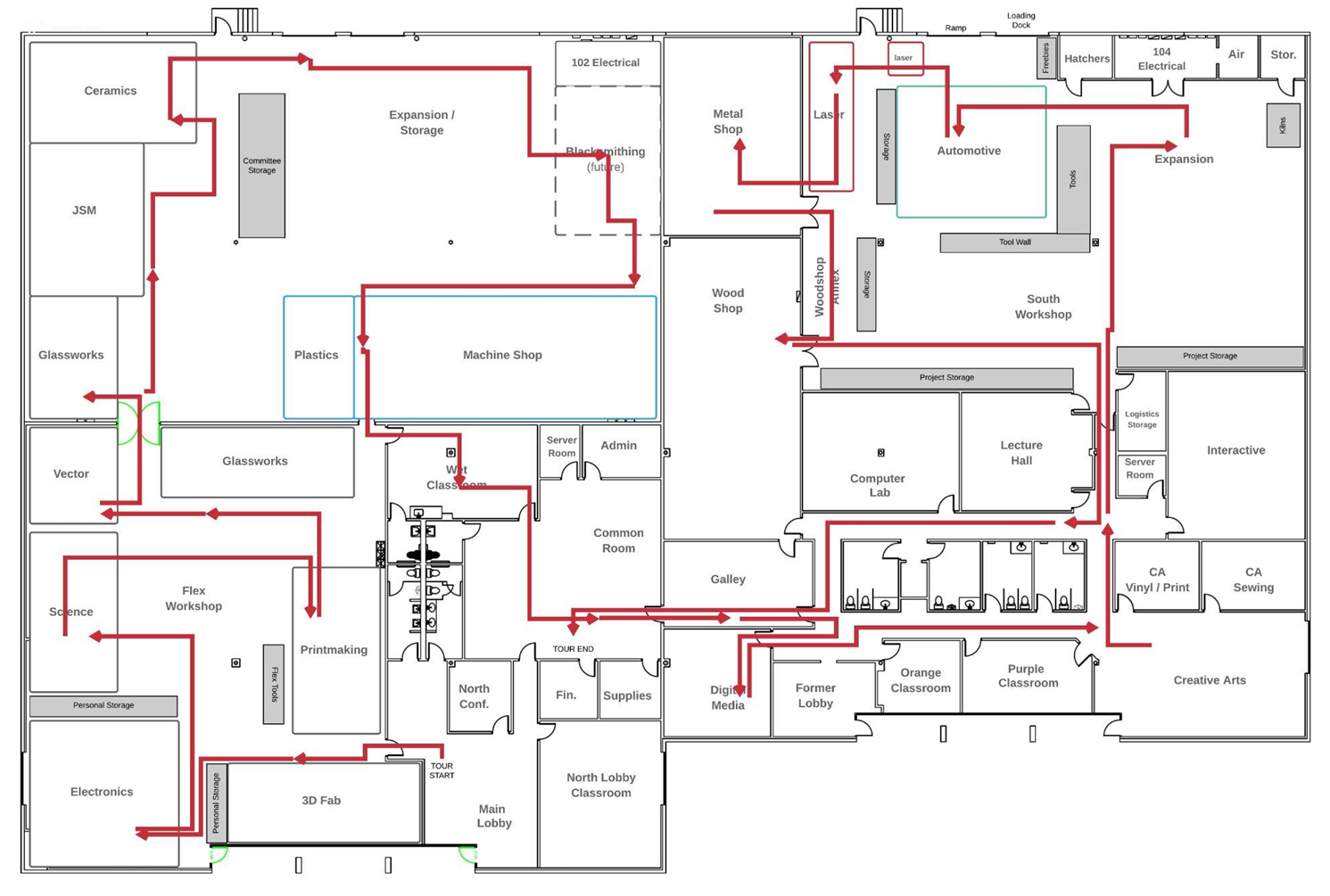

Path

3D Fab

- Polyprinters are our most used printers - can use ABS, PLA, Ninjaflex and several others (we default to ABS, training is required for others)

- Show examples in display case (or bring them out and let people touch them)

- Training is online for both polyprinters and the elegoo resin

- No cost to print, bring your own filament

- Can use our filament in any color, as long as it's orange. Explain the tombstone / square kiosk and that several committees have them to have users pay for consumables

- Other printers can also be used and were donated

- Answer any questions to the best of your ability

Flex Area

- Can work on anything here, just clean up after yourself

- Hand tools, power drops, etc

Electronics

- Very “self serve” committee

- No equipment requires training - they just ask that you ask if you don’t know how to use something - we like keeping the magic smoke inside

- Lots of components and wires for use - if you use a bunch donate

Storage

Only area for personal storage - usually for keeping PPE or small items on site (safety glasses, tape, etc). $20 one-time

Science

- Agriculture / aeroponics

- Fusor - high-voltage electrostatic fusion (hydrogen -> helium)

- Lots of equipment - centrifuges, microscopes, glassware, reagents, etc.

- Previous classes: mushroom growing, lip balm, DNA extraction, basic radioactivity, electroplating.

- Chemicals are kept separate and requires the basic safety class to get access

Printmaking

- Screen Printing - bags, tshirts, paper, etc. We have 6-color and 4-color presses - have everything for making screens here

- Large “Wonkanator” Kluge press - Came out of the DFW airport! Sold at auction and was donated to us

- Letter prints / Block prints - We can use the lasers to lase out some of these, but we can’t do metal yet

- Larger prints - steam roller print events, we’ll hold one this fall (did you know they’ll let anybody rent one of those things?)

- Strictly nontoxic inks in the washout sink.

Glassworks

- We only do “warm” processes here - we can’t maintain a glory hole furnace with volunteer power

- Stained glass, pendants, fusing - we can do all the shaping and cutting out here in this area and do the stained glass soldering as well

- For small objects we have microwave kilns to fuse glass

- The kilns and torches are in the back (glassworks part 2)

Vector

- Vintage Electromechanical Conservancy of Technology, Operation, and Restoration

- PINBALL (and other arcade machines)

- Repair machines, visit shows, etc.

- Tiki machine - Paul Wilson - entire cabinetry and other details done here at DMS using the internals from another machine and restored. Won several awards.

Glassworks part 2

- Kilns for Glassworks - show example of fusing and slumping into a plate

- Lampworking (beads, small amounts of blowing, etc)

- Molds and kiln wash are available

- There is a fee for firing that goes towards maintaining the kilns

Jewelry / Lapidary

- Jewelry always has several examples laid out

- Lapidary - cutting, polishing, and shaping of rocks

- Wire wrapping, beading, etc

- 3D printing wax resin - lost wax casting using our kilns and furnaces

- Jewelry benches - rotary tools, etc

- Torches for soldering are in the fire cabinet

- Kilns for firing molds and melting metals

- Two vacuum casting machines

- Polishing wheels

Ceramics

- One of the cheapest ways you can get into ceramics - classes provide clay and tools, and you can see if you like it

- We have the wheels for throwing, molds for slipcasting, slab roller and molds for hand building

- Community glazes available, just pay for what you use

- We fire on site with a volunteer team (firing squad). We do mid-fires - bisque at 04, glaze at cone 6 and sometimes specialty firings that are voted on.

- Initial class (ceramics 100) to see how the processes work and where things are, and other classes for the different methods. The class is required to work in the space.

This is also where I usually talk about how committees meet once a month - show up and get involved - it helps you know how things work, and you get to work on cool projects together.

Motorsports storage

- As we pass their storage - we field a race car in a few endurance racing events - 24 hours of lemons ( racing for $500 race cars) and champ car

- We work on the car on-site (mid-90s Nissan 240sx). We will teach you how to race and how to work on the car

- It’s been into the wall a few times and blown several engines (which we usually have a few around the storage area)

Blacksmithing

- This will change soon - talk about how we just built the blacksmithing area and how they will have more equipment in there

- Currently have once-a-month open forges where people come and learn outside with the propane forge

- We also have more tools and an induction forge that can be used inside.

Machine Shop

- If people are working, lead the group outside the plexiglass. Otherwise you can walk them through

- Machine shop is for precise machining of metal parts and items, down to thousandths of an inch.

- We have the knee mills and lathes for machine work - and everyone always notices the HAAS 3-axis milling machine.

- Everything in machine shop requires some level of training - the Haas alone takes over 12 hours of training

- Have everything from rough-cutting on bandsaws and cold-cut saws, to fine work with

Many times, this is where I’ll bring up that while we provide some durable consumables (such as drill bits, taps, etc) in various areas, sometimes someone may accidentally break a piece of equipment that you wanted to use. We’re a learning organization, and sometimes that means there are mistakes

This is also why we discourage production commercial work -- you will probably be disappointed and stressed if you really need a piece of equipment to make 20 items you’ve already sold. Have an etsy store, etc! But, you probably want your own equipment if you’re running a business.

Plastics SIG

- Plastics-only area that keeps it out of woodshop and machine show (wears on the tools differently).

- Special tools for cutting and bending plastics - including a vacuum-former

- SIGs are under different committees, some have dedicated areas and resources, and some are just groups that meet to chat or work on common projects.

Wet classroom

- First of the classrooms on the tour (should probably reserve it for tour days once it’s up and running

- We have several classrooms we’ll pass by - this one will be for “messy” classes so that things are tracked around the space

Common Room

- Area where people gather, galavant, carouse, etc.

- Design computers & jump server (can be accessed from anywhere to use some of our software)

Galley

- Mini convenience store - scan and pay - run by Parks Pantry

Digital Media

- Video and audio equipment available for use

- Computers and software for editing and rendering

- Lights and setups for both product photography and green screen shots

- Computers for game design and 3d in the computer classroom

Other Classrooms

- Orange / Purple classrooms - currently closed but being cleaned and reopened shortly

- We have other cool classes: ukulele, moss pole building, writing get togethers, etc

Creative Arts

- Fiber arts - knitting, weaving, spinning

- Painting / Acrylic pours

- Digital - vinyl cutters, dye sublimation (make cool customized stuff!), impact printer

- Sewing room - sewing machines, forms, embroidery, thor (leather sewing)

- Leatherworking - Thor, various hand tools and burnisher - big crossover with blacksmithing for knife sheaths

- Resins - Vacuum/Pressure pots for molds and resin curing

Lecture Hall / Interactive

- Bigger classrooms used for lectures (does what it says on the tin) and a large room for teaching project-based classes with room to work.

South Workshop Flex

- Construction / woodshop expansion storage

- Flex area with a larger selection of power and hand tools

- Power drops and work tables

- Current no project storage, but working on that

Woodshop

- Very full-featured woodshop. If nobody is working and you can, turn off the felder and actually show the tour around. Otherwise I will generally talk about the tools in the shop while standing in the annex, and let folks peek in.

- Larger power tools, covered under our woodshop basics:

- Kapex compound miter saw

- 2 table saws, including a sawstop (drops the blade if you touch it)

- 3 band saws of various sizes

- Multiple sanding units, including a thickness sander

- Jointer / Planer

- Drill press

- 6 Lathes (separate class)

- Multicam - CNC router of 5’x10’x4” (separate class)

- Set expectations about current training - it can be hard to get into classes sometimes, but you may be able to work with someone.

- Most tools are interlocked - that is, you must scan in your RFID badge to actually power on the tool (feel free to demonstrate)

Metal Shop / Blacksmithing

- Where metal comes to be beaten into submission

- Powder coating oven (currently broken - tried to melt itself)

- CNC Plasma cutter - cuts up to ¾” steel (show examples)

- Current blacksmithing area - if allowed you can show the induction forge

- Multitude of tools - cutters, sanders, vapor hone, ring roller, bandsaw, presses.

- Welding - TIG, MIG, Stick, and spot welding. We supply gas, MIG wire costs to run

- No oxy-acetylene, various other rules like no galvanized metals - all taught with “hot process” class

Laser

- 5 lasers

- “Zing” - small portable laser that can go to classrooms

- 3 Thunder lasers - including the larger unit - 120W CO2 lasers that can cut through ½” plywood (if you’re patient). Cannot cut metal, but can mark it

- Fusion laser - 60W RF CO2 laser - can do some finer engraving. Also has a very good rotary tool.

- Lasers charge for run-time, as the tubes are consumable - $1/5min, $2/5min

- Requires basic safety classes

Automotive

- 2-bay automotive - everyone notices the lift, but we can also work in the bay next to the lift

- We are a teaching shop - meaning we allow no commercial work, per our insurance. Must be cars you have “reasonable access” to

- Take-in / Take-out shop - anything that comes in with you (oil, fluids, crappy brake parts) also go out with you

- Lift is a $5 training class, can either ask for training or show up to an autosports or automotive committee meeting

Computer Lab and Common Room

- Walk back through the other hallway - if still up mention occasional events and competitions such as the 10x10s hanging in the hallway

- Mention the computer lab, though don’t focus too much until we get cabling cleaned up :)

Signups

Back to the common room!

Time to try your hand at sales pitch. Encourage people to sign up that day - I usually soft-sell and offer to assist getting people signed up. $60/mo is a great deal for all the tools and space we have. Discounts for students, retirees, military, first-responders are available. Also 10% off for paying yearly.

Sign into the computers for people and go to accounts.dallasmakerspace.org and help them begin to sign up.

- After signing up, they should be immediately available in Maker Manager to enter their badge. Show them where the “member portal” menu is on the main website.

Sign up common problems

- If they already have been a member, they should just use “forgot password” to access their old account, then “add service”

- Username must be all lowercase

- Suggest their password is something they can remember as they’ll need to type it in a lot

- Double-check addresses, zip codes, etc. The payment processor is strict about it, and we have a bunch of people who have just moved coming in

- Waivers - Their name and email must match exactly on their waiver

- Add-on Members - After purchasing on WHMCS, the username, password, etc. is assigned in maker manager under the badges men